LATEST NEWS

Silicon Valley Beer Week

It's one week until Silicon Valley Beer Week and we [...]

Food Trucks and Events at Hapa’s

We have some fun and exciting food trucks and events [...]

Homebrew Competition

We're stoked to announce that we've partnered with local homebrew [...]

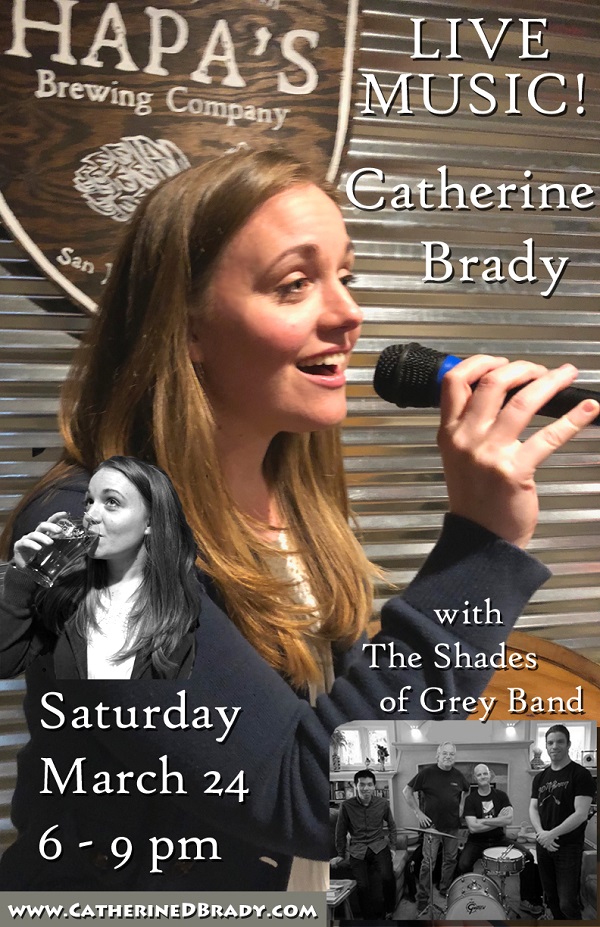

Live Music at Hapa’s

We have a fun week of live music at Hapa's! [...]

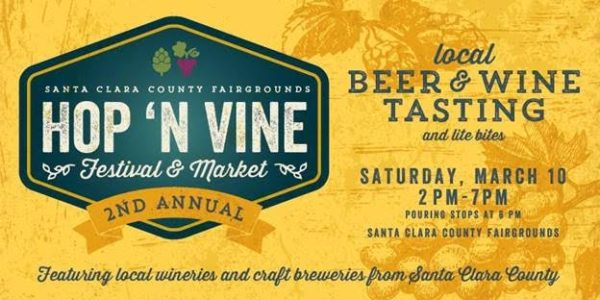

Hop N’ Vine Festival

Hapa's Brewing Co. will be pouring at the Hop N' [...]

Hapa’s One Year Anniversary Party – Details

This day is fast approaching! Hapa's One Year Anniversary Party [...]

OUR NEWSLETTER

Subscribe to our cool newsletter.